Evolving the Edge

Our new Tech Trifecta elevates tool performance

from start to finish.

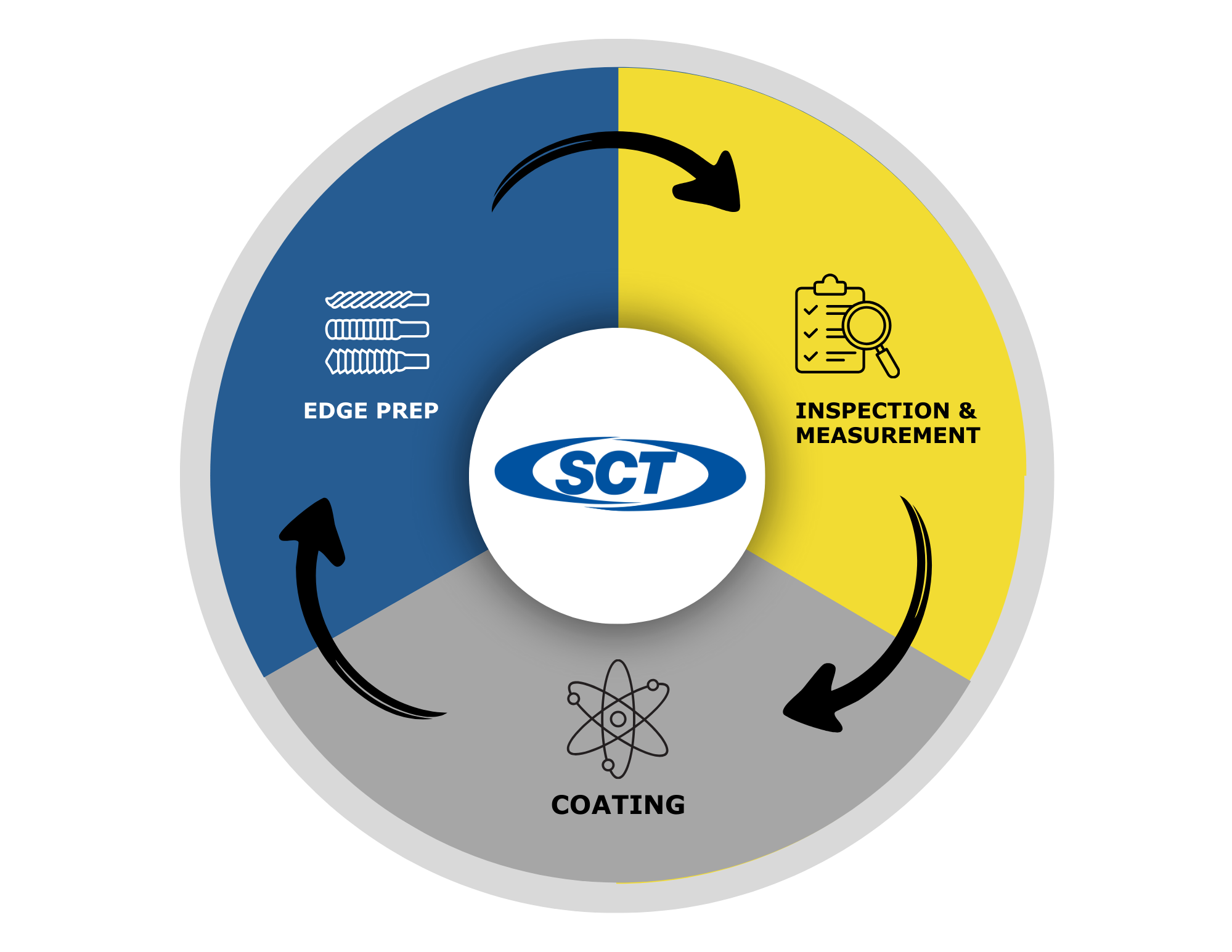

Scientific Cutting Tools is investing in a connected capability stack, spanning edge preparation, metrology, and coating, to reduce performance variation and extend tool life. The result is a more repeatable cutting edge, cleaner verification, and tighter surface engineering.

#1: EDGE PREP

ANCA EPX-SF Edge Preparation

#2: INSPECTION & MEASUREMENT

ZOLLER »genius« + »pomSKPgo« Inspection Suite

#3: COATING

CemeCon CC800 HiPIMS Coating Capability

A connected workflow: Edge Prep → Inspection & Measurement → Coating

Each capability adds value independently, but the leverage comes from treating them as a single system. Edge preparation influences wear and coating adhesion and smooths the edge post-grind. Inspection confirms geometry and provides traceable baselines. Coating provides a protective surface that reduces friction and thermal load at the tool–chip interface, supporting longer, more consistent tool life.

Controlled Edge Preparation stabilizes the cut before it starts

Trifecta #1: ANCA

EPX-SF

Tool life starts at the micro-geometry. With controlled edge preparation on the ANCA EPX-SF, we dial in edge prep features that reduce micro-chipping, stabilize wear progression, and create a stronger foundation for coating adhesion. The result is a cutting edge that enters the cut more consistently, especially when load, heat, and interruptions show up in real production.

What this means for you: Fewer early-edge failures, more predictable wear through the run, and longer usable tool life before the next tool change.

Precision Inspection that proves the edge before it ships

Trifecta #2: Zoller »genius« + »pomSKPgo

Consistency is engineered, then verified. With automated inspection and documented measurement workflows, we confirm critical geometry and edge features so your tools arrive ready to perform, run after run.

What this means for you: More consistent tools, fewer unplanned changes, and less time spent compensating at the machine.

Advanced Coating that protects the edge under heat and load

Trifecta #3: CemeCon CC800 HiPIMS

Coating performance is driven by adhesion, consistency, and how the surface behaves under thermal cycling. With the CemeCon CC800 HiPIMS platform, we expand coating capability with tighter process control and engineered surfaces designed to manage heat and abrasion. That protection helps your tools hold size, finish, and life longer as conditions get more demanding.

What this means for you: More parts per tool, fewer finish surprises as the tool wears, and more confidence when you push cycle time.

Why All of This Matters

Repeatability is not a marketing word. It is the most practical path to lower cost per part.

When cutting performance is consistently strong, you can dial in your process once and build on it. That results in longer tool life, fewer unplanned tool changes, and a tighter handle on cost per part. The Tech Trifecta is how SCT elevates our general purpose tools, with edge prep, inspection, and coating capabilities designed to deliver premium-level durability and reliability in real production, including long runs, mixed materials, and changing loads.

Outcome highlights:

Longer tool life and stronger edge durability in everyday production work

Premium-level performance from a general purpose tool, across a wider range of materials and conditions

More consistent performance across reorders as volumes scale

Fewer unplanned tool changes and more stable run behavior over long cycles

Higher value per tool and lower cost per part when carbide and raw material costs rise

Share your material, tool type, current performance, and what you want to improve. SCT will recommend a next step that fits your needs.

FAQ

Q: Does this change your existing tool families or just manufacturing capability?

A: It is a capability upgrade that improves how tools are built and validated. Product-level changes will be introduced through qualification and documented transitions when applicable.

Q: How will HiPIMS rollout affect current coating options?

A: Your current coating systems will remain fully supported for now. HiPIMS will be introduced in a controlled, phased qualification process to ensure each coating is aligned to specific application requirements. Over the next 12 months, watch for distinct CemeCon HiPIMS coatings launches—Versa (AlCrN) and Ferro (AlTiN)—as they complete qualification.

Q: Is the benefit mainly tool life or also finish and stability?

A: Tool life is a major outcome, and stability and finish often improve because the same variables that drive wear also drive cut behavior.