Single Point Tools

Turn, Groove, and Thread with Confidence

From tight‑tolerance bores to clean grooves and accurate threads, SCT single point tools deliver the control you need. Choose your operation to start shopping.

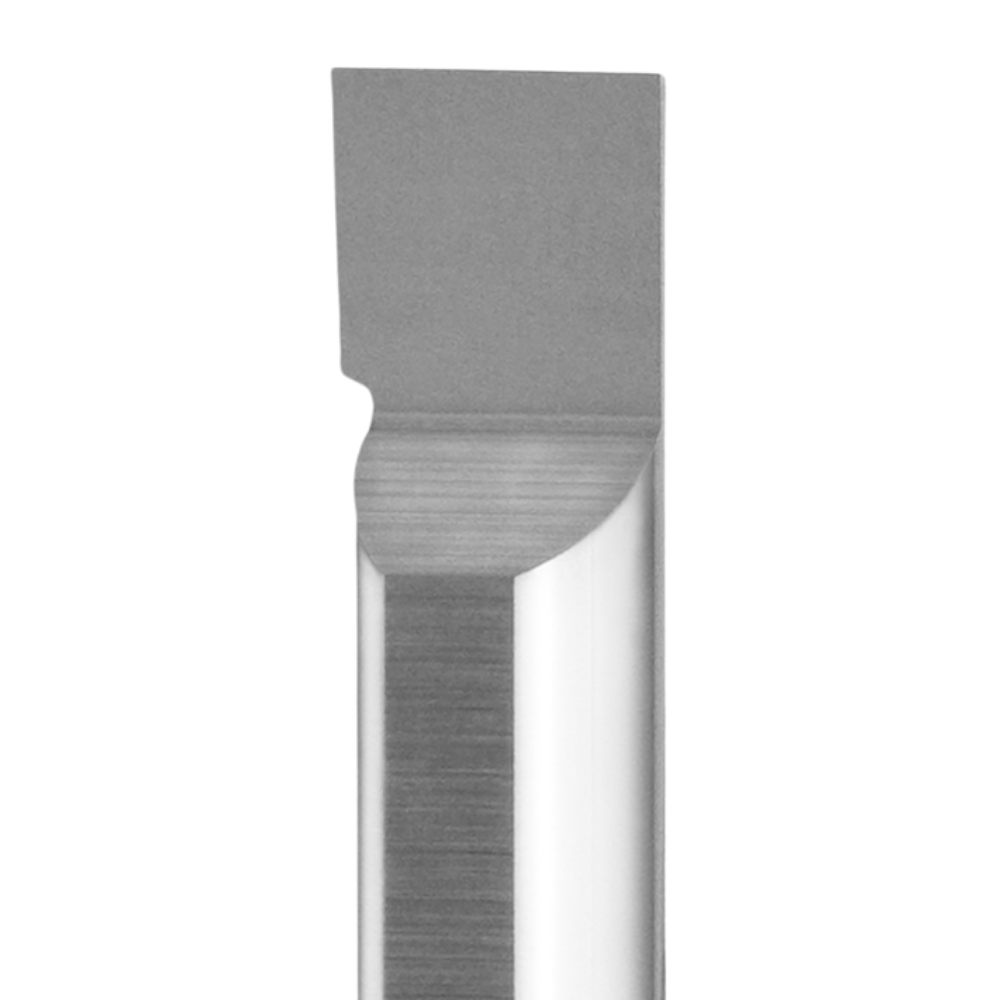

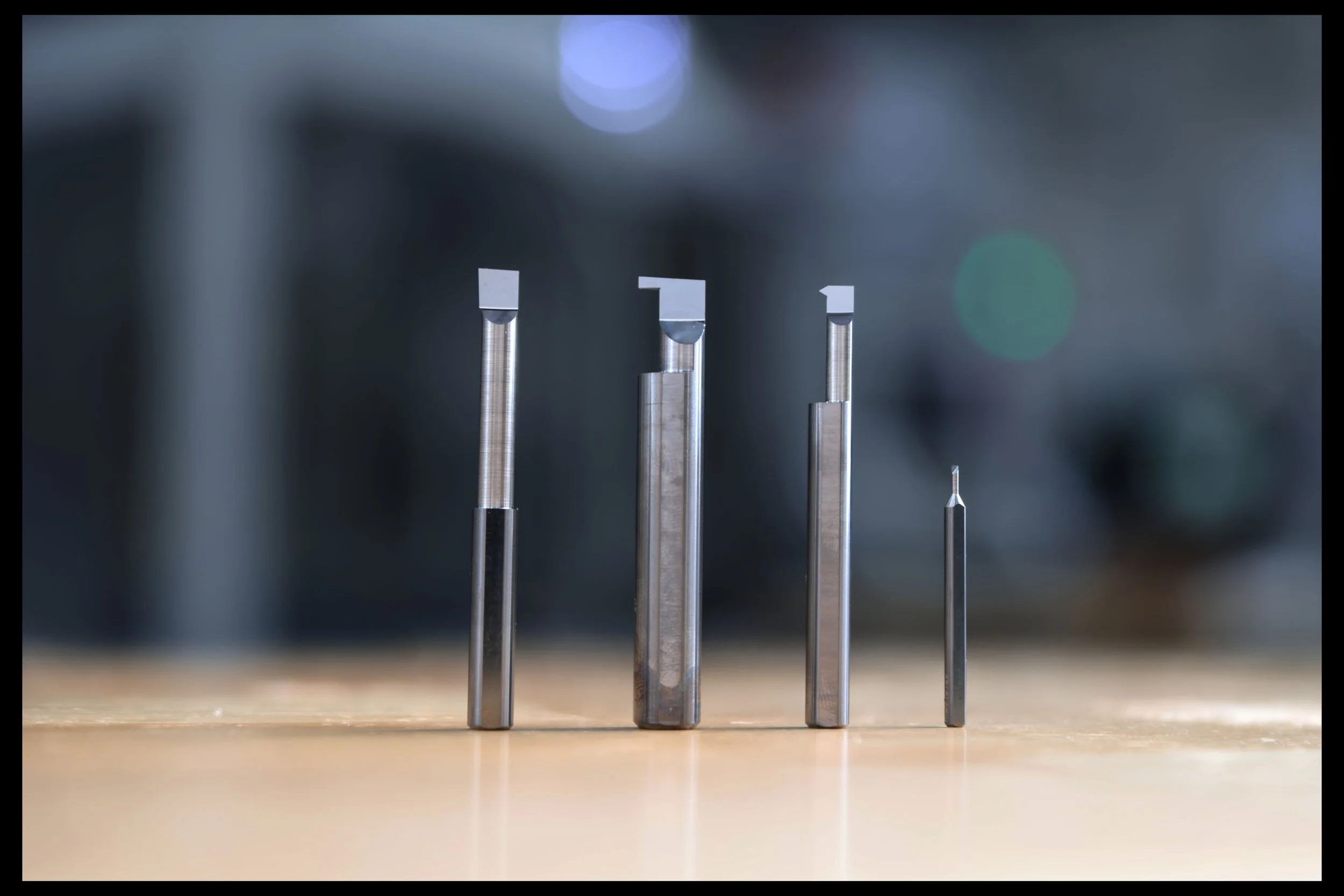

Boring

Internal finishing with tight diameter control

Stable geometries for small bores and long overhangs

Options for fine surface finish on difficult materials

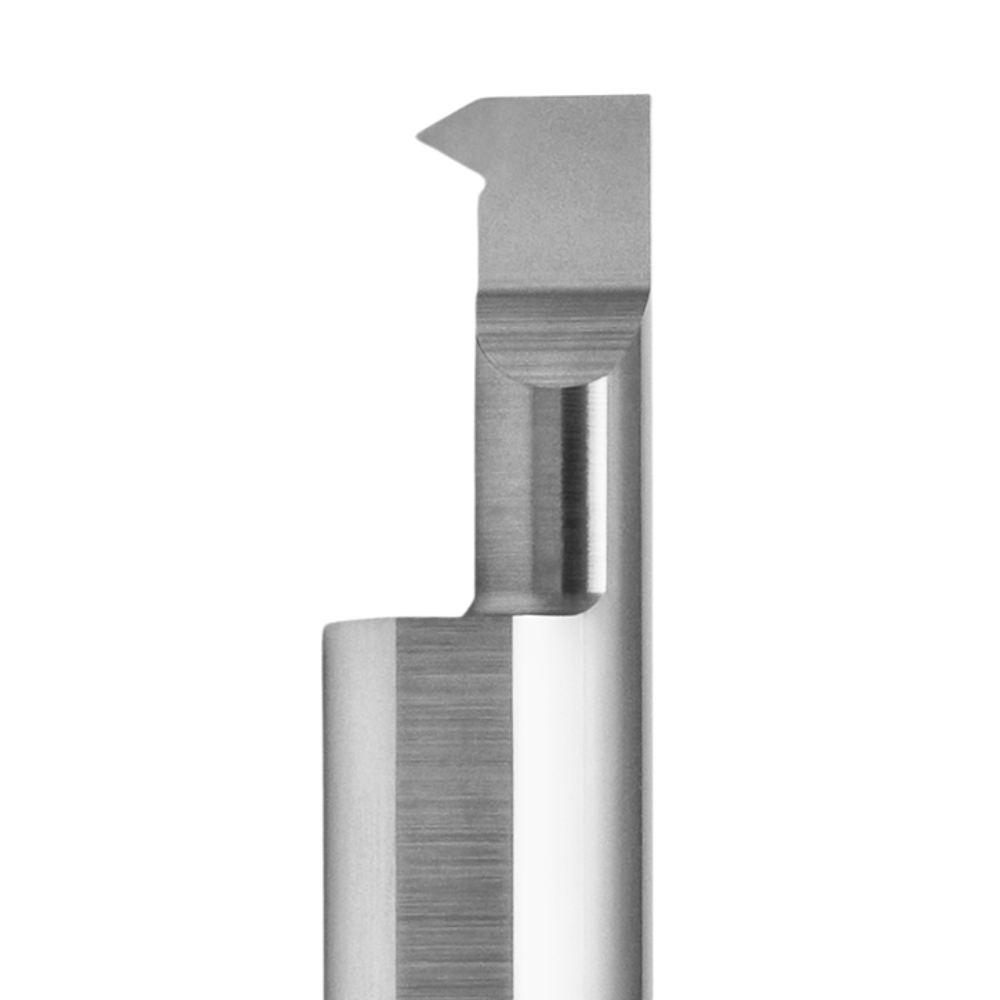

Grooving

Internal and face grooves including O‑ring and retaining features

Consistent groove width with controlled corner radii

Chip control that supports deeper groove depths

Threading

Internal threading including metric, UN, and pipe thread forms

Fine pitch capability and precise thread profile control

Ideal for prototypes and short runs where flexibility matters

Holders

Keep your setup rigid and repeatable.

Pair your cutters with the right holder for shank size, reach, and machine interface.

Designed with SCT single point tools in mind

Wondering which Single Point Tool to use?

This video explains the key differences between boring, grooving, and threading tools and how to choose the right one for your internal feature.

Albert Orantes, DeKING Precision

“If anybody said to me, I’m having issues with this internal operation, whether it’s boring or grooving or threading, I’d send them straight to Scientific because they make it so simple to find what you need and be able to use it right away.”

Support That Starts

Before the Cut

We don’t just sell port tools. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your porting strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.