Single Profile Thread Mills (SPTM)

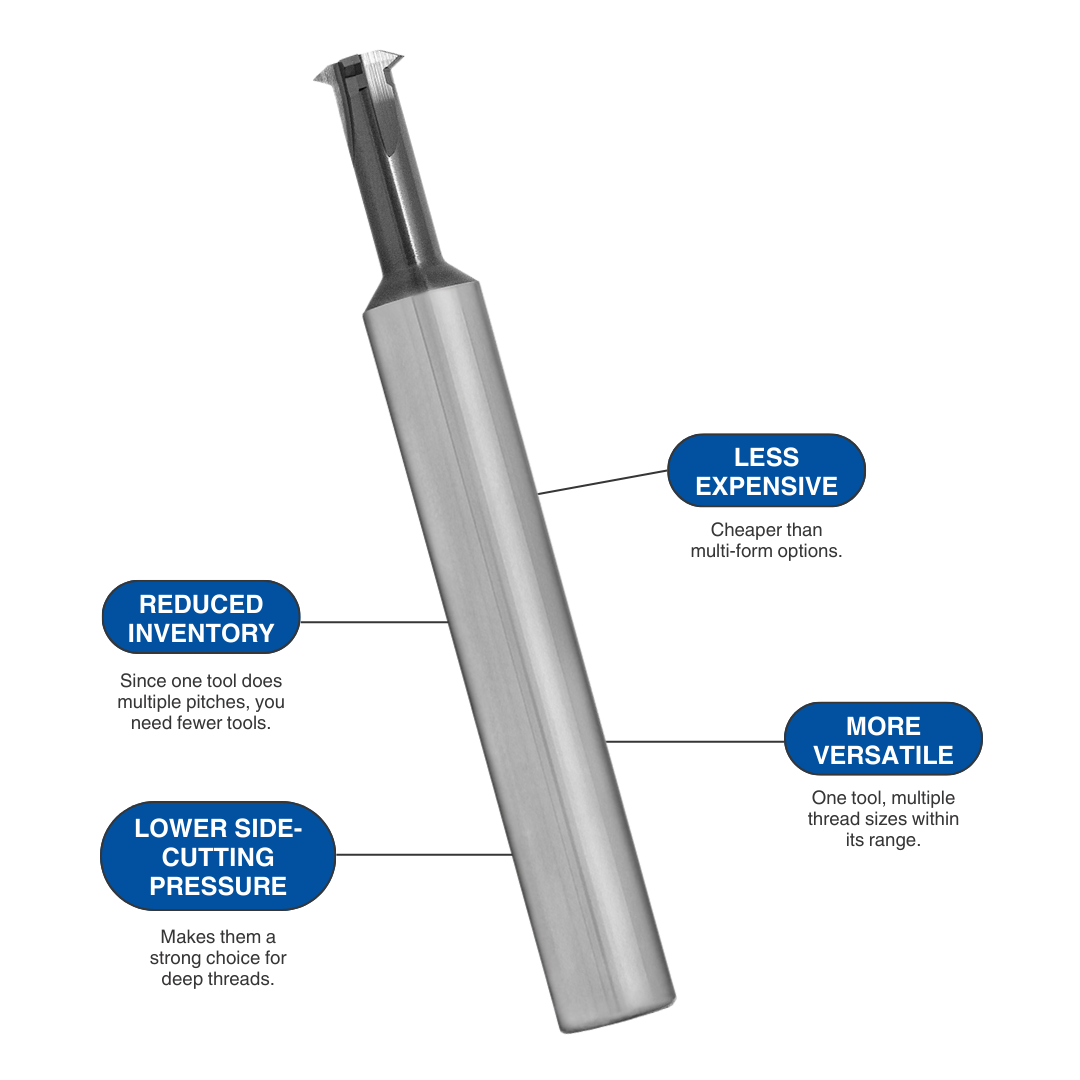

Lower cost, more versatile threading with less side pressure for deep threads.

Choose Your Thread Standard

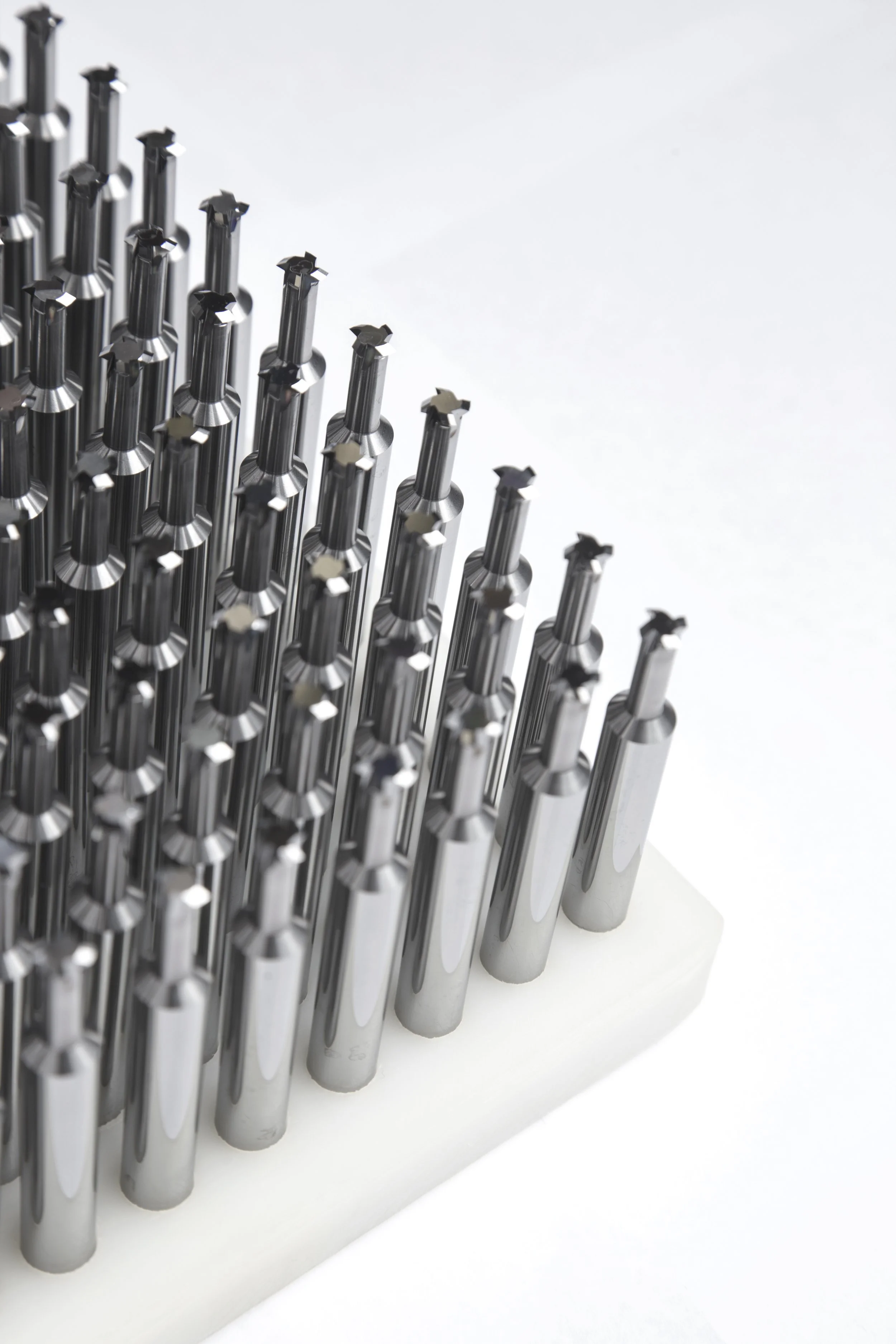

Available SPTM Variations:

UN (Unified)

Standard Unified National threading

Ideal for general-purpose threading in North American applications

UNJ External

External threading with root controlled radius

Common in aerospace and high-performance assemblies

Designed for fatigue resistance

Metric

ISO metric threading options for

international standardsAvailable in coarse and fine pitches

Optimized for global compatability

ACME

Strong, load bearing profile

Used in linear motion applications

Multiple pitch and class options available

Stub ACME

Strong, load bearing profile

Used in linear motion applications

Multiple pitch and class options available

Custom Threads

We machine to your specs - whether

it’s form, pitch, or coatingIdeal for R&D, specialty OEM applications, and problem-solving

Submit a drawing or consult with our engineering team

Why single profile?

SPTMs deliver reliable thread quality with a simpler, more flexible tooling strategy. They are often lower cost, more versatile, and able to cover multiple pitch sizes, while generating less side pressure.

Frequently Asked Questions

Q: What is a Single Profile Thread Mill (SPTM)?

A: An SPTM is a thread mill that forms one thread profile at a time, which makes it a flexible option for producing a variety of thread sizes and pitches without needing a dedicated multi-form tool for every thread.

Q: Why choose an SPTM instead of a tap or multi-form thread mill?

A: Shops choose SPTMs because they’re often less expensive, more versatile, and can cover a range of pitch sizes while generating less side-cutting pressure.

Q: How can one SPTM cut a range of pitch sizes?

A: Because the tool is single profile, you can program different thread pitches via the toolpath (helical interpolation) within the tool’s intended range, reducing the number of thread mills you need to stock.

Q: Are SPTMs better for deep threads?

A: Often, yes. SPTMs tend to create less side-cutting pressure, which helps keep the cut stable as depth increases (less tool deflection, less “push-off,” and more consistent results).

Q: Will SPTMs help reduce tooling cost and tool crib complexity?

A: That’s one of the biggest advantages. When an SPTM can cover multiple pitches/sizes, you can reduce tool count, simplify inventory, and avoid buying dedicated tools for every single thread callout.

Q: What thread forms do you offer in SPTMs?

A: We offer SPTMs in UN, Metric, UNJ, ACME, and Stub ACME, so you can keep the same versatile approach across common thread standards.

Q: When should I not use an SPTM?

A: If you’re running very high volume on one exact thread and want maximum throughput, a dedicated solution (like a multi-form tool) may be faster. We’ll help you choose based on cycle time goals, material, and required thread quality.

Support That Starts

Before the Cut

We don’t just sell tools—we back them with the knowledge and support you need to machine with confidence. Whether you're looking to sharpen your threading strategy or need help on a current job, these resources are here to help.

Thread Milling Webinar. Watch our on-demand webinar to deepen your understanding of thread milling fundamentals, tooling selection, and programming best practices.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Thread Mill Code Generator. Our calculator takes the guesswork out of programming. Generate your thread milling code based on your specs.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.